2019Milling clamping tool user guide information catalog

1. Turning part

(01)Turning tool-the relationship between cutting resistance, cutting conditions, tool shape

(02)Turning tool-turning processing calculation method

(03)Turning tool-calculation of cutting resistance

(04)Turning tool - Measures to troubleshoot turning processing failures

2. Integral hard end mill

(01)Integral hard end mill load grinding steps

(02)Integral hard end mill - measures to troubleshoot end mill processing failures

3. Drilling tool

(01)Drilling tool-Cutting damage of integral carbide drill bit

(02)Drilling tool-Measures to eliminate machining failures of the overall cemented carbide drill bit

(03)Drilling tool-indicable drill bit parts name

(04)Drilling tool-cut shape

(05)Drilling tool-Measures to troubleshoot the processing fault of indexable drill bits

(06)Drilling tool-Measures to troubleshoot gun drilling processing failures

(07)Drilling tool-Measures to troubleshoot gun drilling and reaming faults

4. Cooperation IT grade

5. Match the dimensional tolerance shaft

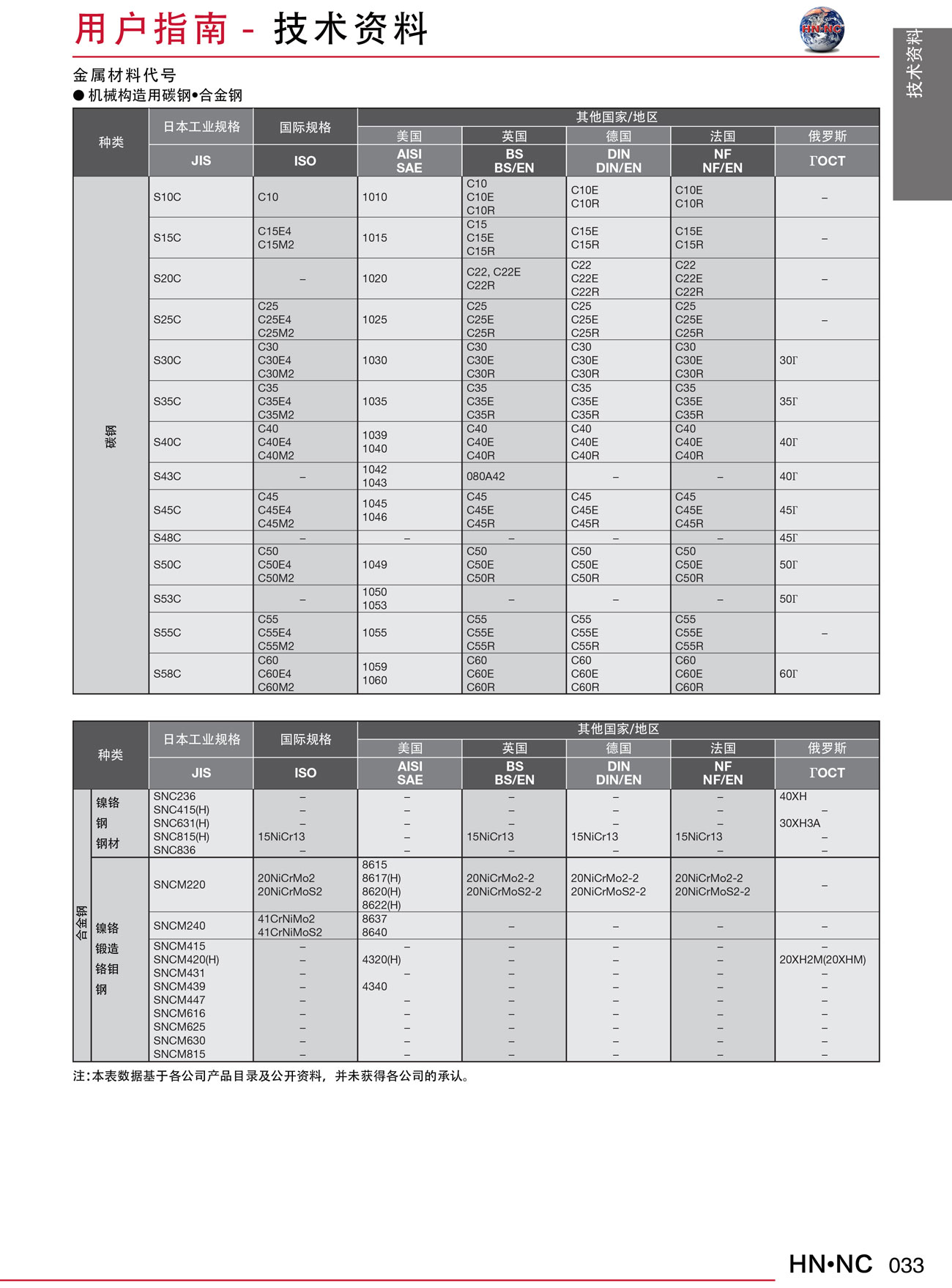

6. Metal material code

(01)Carbon steel and alloy steel for mechanical structure

(02)Metal material code-alloy steel /Stainless steel

(03)Metal material code-stainless steel

(04)Metal material code-heat-resistant steel /Tool Steel /Special purpose steel

(05)Metal material code-cast iron and casting parts /Non-ferrous metal

(06)Metal material code-non-ferrous metal

7. Hardness approximation conversion table

8. Surface roughness

9. Material comparison table

(01)Material comparison table for each company - for turning CVD Coating material

(02)Material comparison table for each company - for turning PVD Coating material

(03)Material comparison table for each company - Metal cermet for turning

(04)Material comparison table for each company - Cemented carbide for turning

(05)Material comparison table for each company - for turning PCBN and PCD

(06)Material comparison table for each company - Ceramics for turning

(07)Material comparison table for each company-for milling CVD Coating material

(08)Material comparison table for each company-for milling PVD Coating material

(09)Material comparison table for each company-for milling PVD Coating material

(10)Material comparison table for each company - Metal cermet for milling

(11)Material comparison table for each company - Cemented carbide for milling

10. Blade cutting groove comparison table

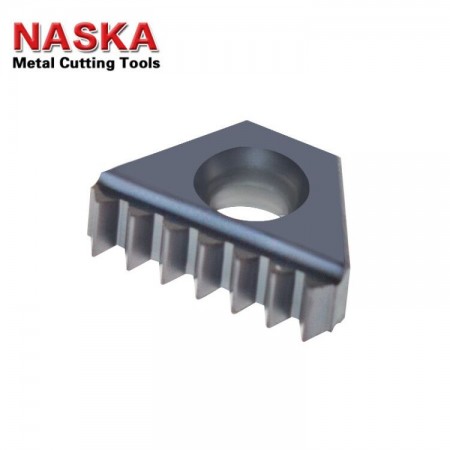

(01)Comparison table of blade cutting grooves for each company - Negative front angle type

(02)Comparison table of blade cutting grooves for each company - positive front angle type

11. Unified number of cutting conditions and tool size

12. Milling tool size code