2020The thread milling cutter information is a detailed technical document covering specific information on various types of thread milling cutters.Here is an overview of the main content of this information:

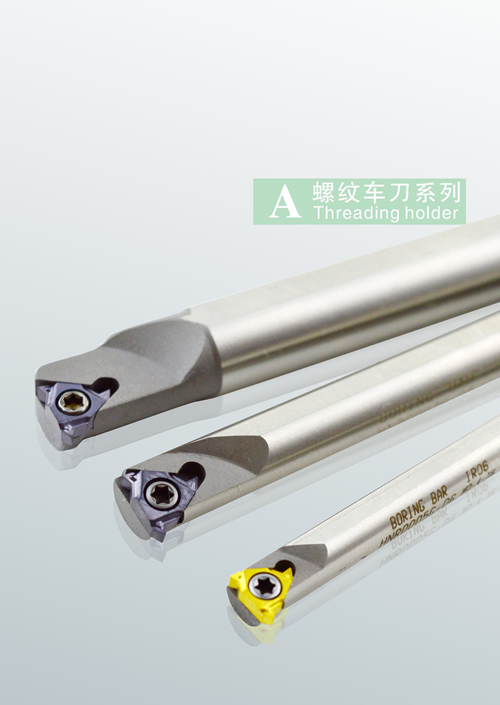

HSMT Series: Introduce the blade size used for single-edge thread grooved milling rods and their recommended processing parameters.

SR Series: Provides detailed description of threaded milling cutter plates, including guides on blade size and corresponding machining parameters.

SMT Series: Similar to HSMT Series, this section focuses on single-edged threaded grooved milling cutting rods and provides relevant information on their blade size and machining parameters.

SR Tungsten Steel Series: Specially described for threaded milling rods made of tungsten steel, listing the insert size and processing parameters.

SR Three-edge Series: Explain the design details of the triple-edge threaded milling rod, as well as the corresponding blade size and recommended machining parameters.

SR Triple-edge thread milling cutter plate series: Provides data on the insert size and machining parameters of the triple-edge thread milling cutter plate.

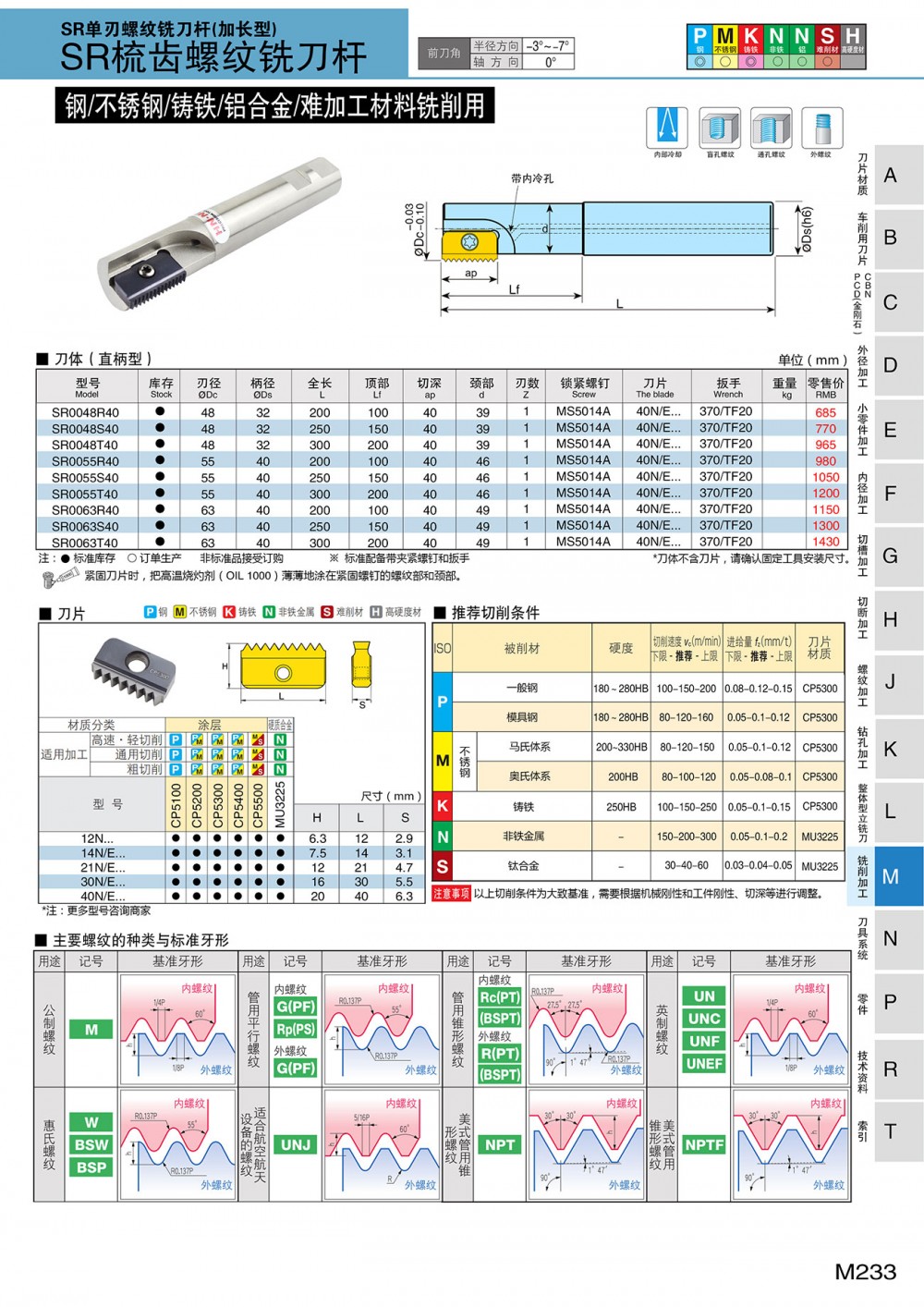

SR Comb tooth series: It introduces the blade size of threaded milling rods designed by comb tooth and its applicable machining parameters.

SR Comb Tooth Extended Series: Designed for extended comb toe thread milling rods, providing detailed insert size and machining parameters.

SR Double-edged comb tooth series: covers the insert size and recommended machining parameters of double-edged comb tooth thread milling rod.

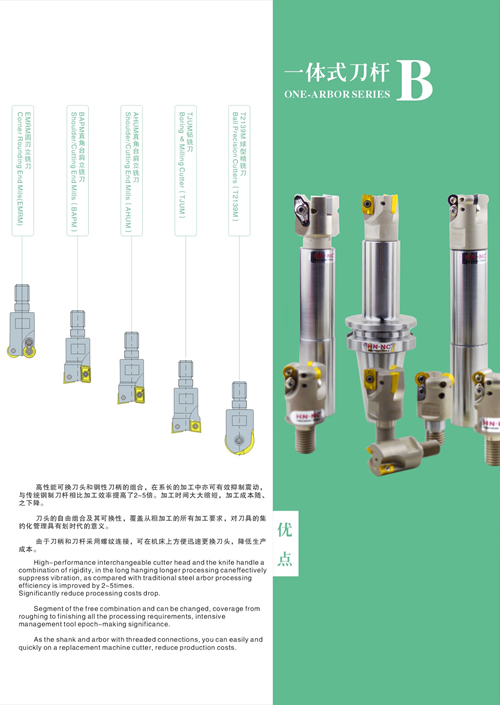

TMSD Standard series: It is divided into two parts: cutter plate and cutter rod. Each part lists the blade size and processing parameters of the standard tool in detail.

V27 Series: Focus on V27 Thread milling cutter plate, providing its blade size and corresponding processing parameters information.

This information is intended to provide technicians and engineers with the necessary reference data to ensure optimal decisions can be made when selecting the appropriate thread milling cutter and setting machining parameters.By rationally utilizing this information, production efficiency and product quality can be effectively improved.